Scarf Joint Template

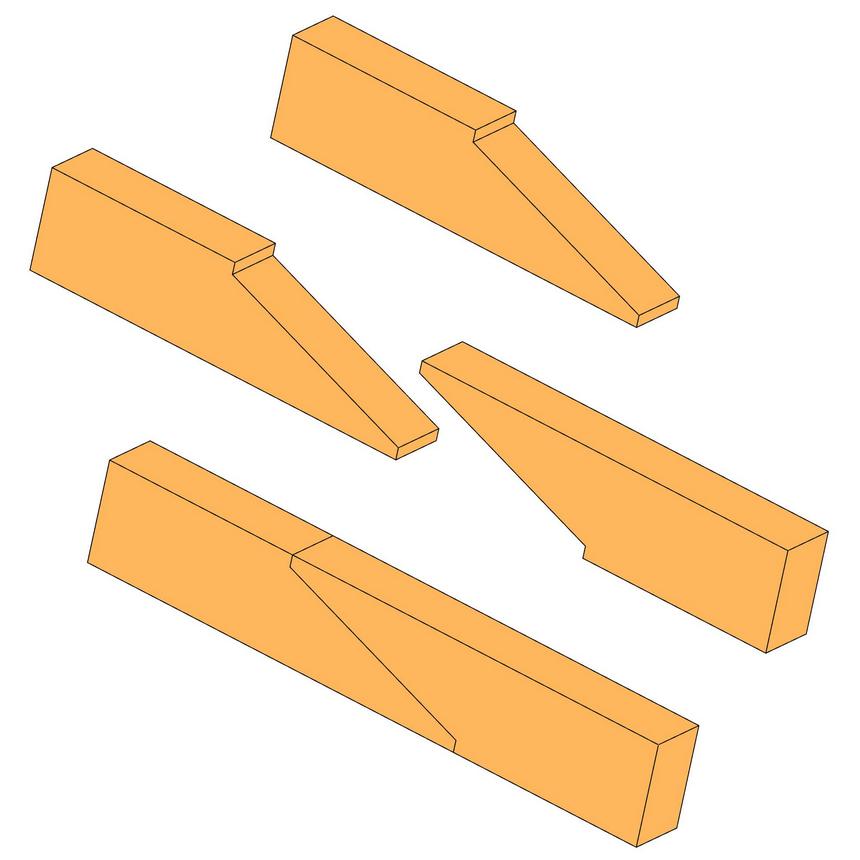

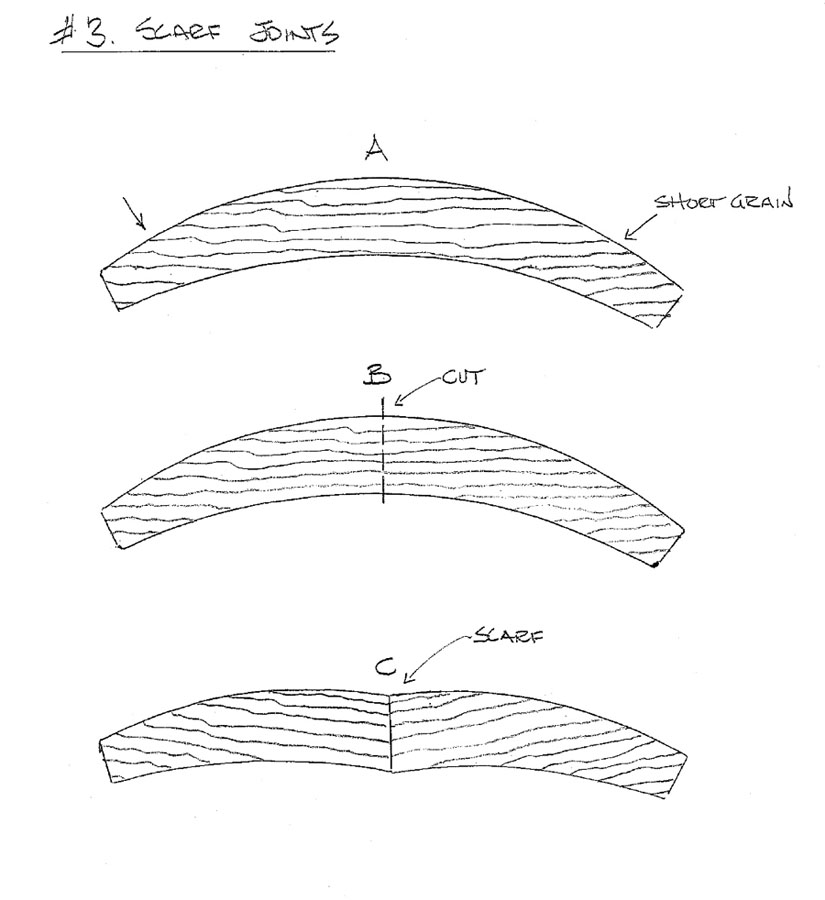

Scarf Joint Template - Web learn how to make a scarf joint; In this detail, we illustrate three types of methods to connect the two beams and joints together. Please note that the preferred method for scarf joint. Scarf joints have been used in shipbuilding and woodworking for thousands of years for their strength and simplicity. Web nothing beats the look and strength of an undersquinted scarf joint with a wedge. Web bevel cut scarf joints: In addition it locks together and minimizes the amount of clamping required. Web puzzle joinery allows short panels to be rapidly and easily assembled into longer ones. The secret to this jig is using an inlay cutter bit and bushing in your router. The back hoop and the right and left arms. When extending the length of the boards, this technique is frequently used. Web a great way to lock together long pieces of 4mm okoume plywood and instead of trying to disguise the joint you showcase it. Web puzzle joinery allows short panels to be rapidly and easily assembled into longer ones. Please note that the preferred method for scarf joint.. 1/8 inch mahogany door skin. Web so, this video treat is a slick little way to get some template advice: Web puzzle joinery allows short panels to be rapidly and easily assembled into longer ones. When extending the length of the boards, this technique is frequently used. I make the back/arm from three separate components: Measuring tape or ruler and a pencil; Web the method known as scarfing is used for the joining of timber in the direction of its length, enabling the workman to produce a joint with a smooth or flush appearance on all its faces. Web there are many variations of scarf joints to be found and each of them has a. The secret to this jig is using an inlay cutter bit and bushing in your router. Most traditional sawmills are not equipped to handle wood that is much over 30′, if even that! Web so, this video treat is a slick little way to get some template advice: Please note that the preferred method for scarf joint. Why door skin. Descriptions and characteristics of these types of joints. Design and placement [ re: Web this paper summarises the current state of knowledge related to scarf and splice carpentry joints in flexural elements, also providing some examples of tensile joints. When trying to determine which joint is best for your situation you need to understand the loads and forces that will. Two boards to be joined; Web using the scarf joint to gain length in your timber frame. The back hoop and the right and left arms. You can cut it with a knife; When extending the length of the boards, this technique is frequently used. They are created by cutting one end of the material at an angle and joining it to the other piece with a butt joint. The back hoop and the right and left arms. Web a great way to lock together long pieces of 4mm okoume plywood and instead of trying to disguise the joint you showcase it. 1/8 inch mahogany. That way, you'll only see the seam on moving day. Scarf joints can build stronger connections than regular butt joints while staying easy to make. When extending the length of the boards, this technique is frequently used. Web nothing beats the look and strength of an undersquinted scarf joint with a wedge. [1] the scarf joint is used when the. Behind a door is another good spot, but be careful of positioning a joint too close to a corner. Web puzzle joinery allows short panels to be rapidly and easily assembled into longer ones. Web there are many variations of scarf joints to be found and each of them has a function that they excel at over other scarfs for. Web the method known as scarfing is used for the joining of timber in the direction of its length, enabling the workman to produce a joint with a smooth or flush appearance on all its faces. Why door skin makes great woodworking templates: Please note that the preferred method for scarf joint. Web nothing beats the look and strength of. When timber framing a large structure, the problem will invariably arise how to get enough length out of your plates. Web cut the scarf first, assemble it and bore any peg holes dead last, after all fitting is completed. In addition it locks together and minimizes the amount of clamping required. Design and placement [ re: The secret to this jig is using an inlay cutter bit and bushing in your router. Web a scarf joint, or scarph joint, is a method of joining two members end to end in woodworking or metalworking. The first uploaded photo above shows the guide and bushing. This is a full sized template for tracing out a scarf joint on the end of a timber. Then, using a modified scarf joint, i join them into a single crest. A scarf joint is one that uses an angled cut to mate two pieces of wood with fasteners or glue. Two boards to be joined; Scarf joints come in many shapes, but the main purpose is the same: When trying to determine which joint is best for your situation you need to understand the loads and forces that will be working against the joint. I make the back/arm from three separate components: Puzzle joints are an interesting alternative to scarf joints, butt joints, and fiberglass tape butt joints. Web scarf joints are an efficient way to secure two short pieces of wood, but what is the best way to make one?

Scarf Joint With A Wedge Timber Frame HQ

Scarf Joint Template 3″ and 31/8″ — Bob's Wood Stuff

![36 Woodworking Joints EASY To Make [2019 update]](https://baubeaver.de/wp-content/uploads/woodworking-joints-Oblique-pinned-scarf-joint.png)

36 Woodworking Joints EASY To Make [2019 update]

Scarf Joint CAD/PDF Plans — KatzMoses Woodworking

Scarf Joint for Wood Elegance and Strength Don Tai (Canada) Blog

Scarf woodworking joints CRAFTSMANSPACE

Making Scarf Joints Woodworking Blog Videos Plans How To

![36 Woodworking Joints EASY To Make [2019 update]](https://baubeaver.de/wp-content/uploads/woodworking-joints-Oblique-hooked-scarf-joint.png)

36 Woodworking Joints EASY To Make [2019 update]

Scarf Joint Timber Frame HQ

Tablesaw Jig for Making Scarf Joints FineWoodworking

Behind A Door Is Another Good Spot, But Be Careful Of Positioning A Joint Too Close To A Corner.

Requires A Table Or Miter Saw.

Descriptions And Characteristics Of These Types Of Joints.

Web This Jig Builds A 'Scarfed' Neck Joint.

Related Post: