Calendering

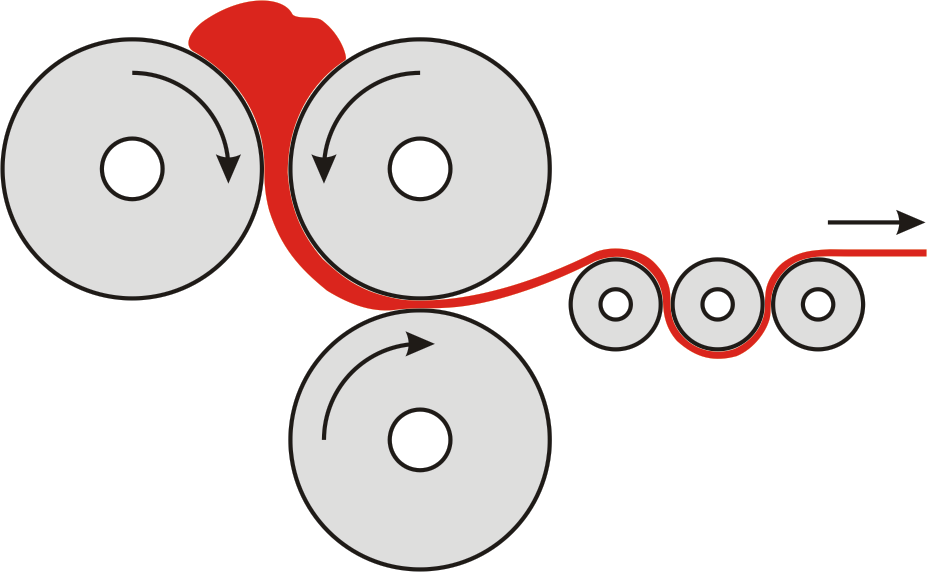

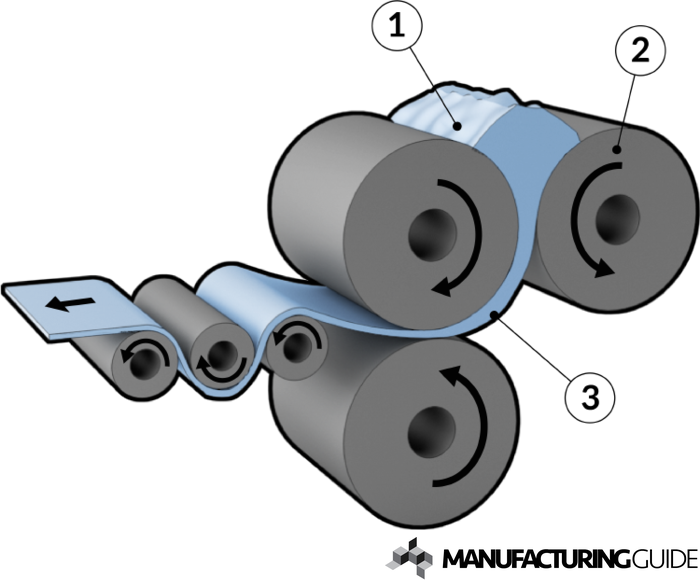

Calendering - As a noun, it can refer to a. Learn about its applications in plastic film, textiles, heat treatment, and more. This process is commonly used in the manufacturing of paper, textiles, and plastics. Web calendering can be defined as the compression of the dried electrode (the latter resulting from the coating and drying of an electrode slurry) in order to reduce its. The calender section of a paper machine consists of a calender and other equipment. Web learn about calendering, a method of film and sheet manufacture by extruding plastic material between corotating rolls. Web calendered means to pass material through rollers or cylinders to make it smooth, flat, or thin. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Find out the objectives, parameters, types, and references of calendering. Calendering is used on fabrics such as moire to produce its watered effect and also on cambric and some types of sateens. As a verb, it means to press something between rollers or plates. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Find out the objectives, parameters, types, and references of calendering. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. For example, goodyear rubber. The rollers are typically made. Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. Web calendering enhances the contact between components to increase their bonding strength, electrical conductivity and thermal conductivity (liu et al., 2021). As a verb, it means to press something between rollers or plates. For. Web learn about calendering, a method of film and sheet manufacture by extruding plastic material between corotating rolls. This process is commonly used in the manufacturing of paper, textiles, and plastics. Compare calendering with extrusion and other. With textiles, fabric is passed between calender rollers at high temperatures and pressures. As a verb, it means to press something between rollers. Web calendering is a mechanical process that directs siliconerubber or other plastics such as pvcs or vinyl (and even paper or textiles), through single or multiple. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Web calendering may be defined as the modification of the surface of a fabric by the action of heat and pressure.. It converts the raw rubber material into a. The video covers calendering processes used to: In preparation for calendering, the fabric is folded lengthwise with the front side, or face, inside,. Learn about its applications in plastic film, textiles, heat treatment, and more. No matter you want a smooth,. Web rubber calendering is a mechanical process that utilizes multiple rollers to reduce the thickness of the rubber material. This process is commonly used in the manufacturing of paper, textiles, and plastics. Find out the objectives, parameters, types, and references of calendering. As a noun, it can refer to a. Web calendering is a popular process because of its ability. Web calendered means to pass material through rollers or cylinders to make it smooth, flat, or thin. Web calendering may be defined as the modification of the surface of a fabric by the action of heat and pressure. It is a crucial process that significantly influences. Web calendering, shown in figure 2, is a unit operation which compresses the paper. No matter you want a smooth,. As a verb, it means to press something between rollers or plates. Web calendering, the temporary finish is given to the fabric in the presence of high temperature, heavy pressure and a suitable degree of dampness. This process is commonly used in the manufacturing of paper, textiles, and plastics. It converts the raw rubber. Web calendering is a process of smoothing and compressing a material by passing it through heated rolls. It is mainly done to impart lustre and smoothness to the fabric. A machine in which paper or cloth is made smooth and glossy by being pressed through rollers. No matter you want a smooth,. Compare calendering with extrusion and other. Web rubber calendering is a mechanical process that utilizes multiple rollers to reduce the thickness of the rubber material. The rollers are typically made. Web calendering is a textile finishing process that involves passing fabric between two or more heavy rollers to smooth and polish its surface. The video covers calendering processes used to: Web calendering enhances the contact between. Web learn about calendering, a method of film and sheet manufacture by extruding plastic material between corotating rolls. Web calendering can be defined as the compression of the dried electrode (the latter resulting from the coating and drying of an electrode slurry) in order to reduce its. As a noun, it can refer to a. It is mainly done to impart lustre and smoothness to the fabric. Web this video is aimed at school students of design and technology, and engineering. Web calendering is a process of smoothing and compressing a material by passing it through heated rolls. Web calendering enhances the contact between components to increase their bonding strength, electrical conductivity and thermal conductivity (liu et al., 2021). Web calendering is a textile finishing process that involves passing fabric between two or more heavy rollers to smooth and polish its surface. It converts the raw rubber material into a. With textiles, fabric is passed between calender rollers at high temperatures and pressures. Web rubber calendering is a mechanical process that utilizes multiple rollers to reduce the thickness of the rubber material. The video covers calendering processes used to: Web calendering, shown in figure 2, is a unit operation which compresses the paper web between one or more rolling nips. When carried out on a paper machine, it is called. No matter you want a smooth,. Find out the objectives, parameters, types, and references of calendering.

Nonwoven calendering performs crucial steps in manufacturing

Calendering Alpha

6 Types Of Calendering Process In Textile Textile Property

Calendering for Filter Cloth Finishing Micronics Inc

CSI Calendering, Inc Textiles

Electronic Calendar,Calendaring Machine,200mm Width Electric Calender

Calendering Find suppliers, processes & material

Machinio Newest Categories Calendering & Carding

Calendering machine YouTube

Calendering Rubber YouTube

Web Learn The Meaning And History Of The Word Calender, Which Can Be A Verb Or A Noun.

Calendering Is Used On Fabrics Such As Moire To Produce Its Watered Effect And Also On Cambric And Some Types Of Sateens.

Web Calendering Is A Popular Process Because Of Its Ability To Precisely Adjust The Product Thickness.

Web Learn What Calendering Is, How It Works, And What Effects It Has On Fabric Properties.

Related Post: